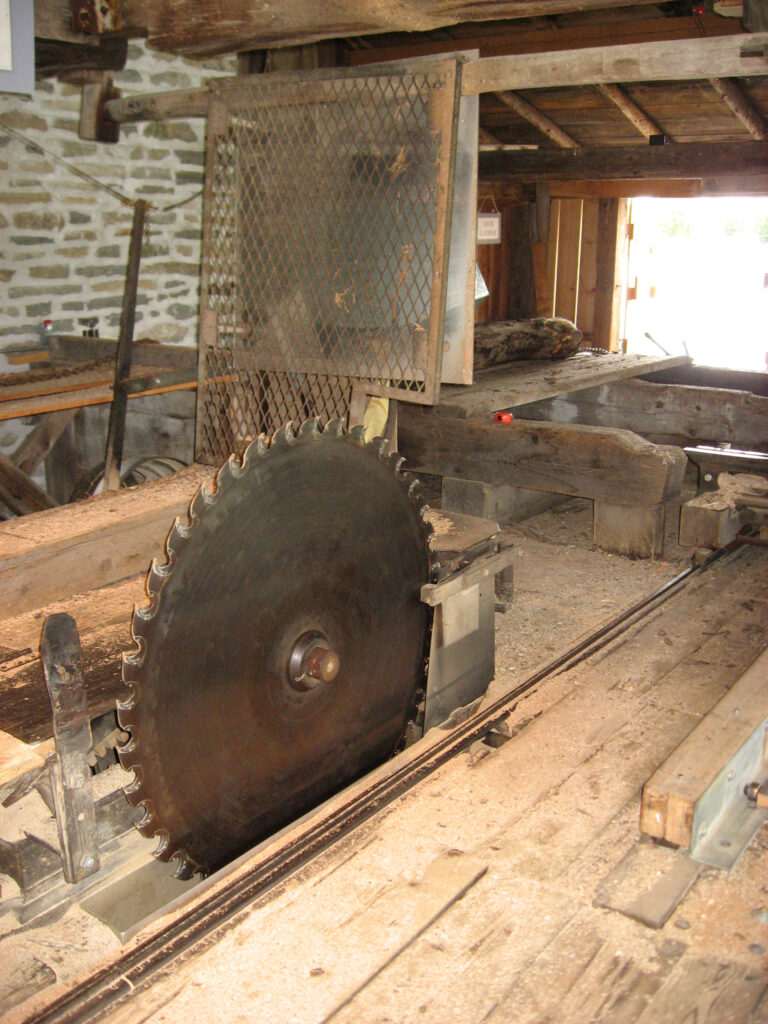

Today, our logs are brought in by truck once the roads are able to handle the weight. The logs are dropped at the edge of the millpond and quickly rolled into the water which protects them somewhat from insects. The saw team begins the milling process by guiding the logs in the millpond with a long pike-pole over to the jack-ladder where the logs are chained and winched by water-power up into the mill. The cant man then uses a cant hook to roll a log onto the saw carriage where it is secured with dogs. The present-day system can cut logs up to sixteen feet long and 24 inches in diameter. The present saw blade is 48 inches in diameter with 38 replaceable, inserted teeth. When John Miller Hope was running the mill (1931-1966) the saw blade was 55 inches which meant that he could handle larger logs. When the sawyer engages the water power, the saw-blade rotates at 500 r.p.m. and the carriage is drawn along its rails by a rack and pinion gear, bringing the log into contact with the saw. The cut pieces of lumber are removed for stacking and the waste wood is rolled along to the cut-off saw and is cut into firewood lengths.

Safety Features

To meet present-day requirements various safety features have been added to the sawing operation, the finishing machines, the building and the dam.

Lumber Available for Sale

The saw is operated to demonstrate pioneer lumbering techniques for our visitors. We cut mostly softwoods (pine and cedar) and that wood is available for purchase. Occasionally, we have some hardwood, such as maple and basswood. We also do custom sawing, cutting to exact customer specifications. With the installation of the solar powered kiln, we now have kiln dried wood for sale. For further information about custom sawing and about our current inventory of lumber please contact Alex McCubbin.

Solar-Powered Kiln

A hundred years ago, fresh cut lumber was air-dried outdoors. Depending on the type of wood, the drying process ranged from 6 months to two years. Wood must be dried before it can be machined into finished lumber.

Since 2006, Hope Mill Restoration Volunteers have been successfully sawing lumber using the original water-powered turbines, with a combined force of 75 horsepower. Space to air-dry and store the lumber became an issue.

One of the volunteers found a reference to solar-powered kilns on the Internet. We were on our way! We decided that we would use some of the Hope Mill lumber to build the kiln. Now operational, it has reduced the drying time to 2-3 weeks for most of the soft- and hardwood sawn lumber.

The design is relatively simple and highly effective! Based on a 6’ by 12’ floor plan, the kiln will hold a 4’ by 4’ by 10’ pile of planks, spaced with stickers to allow airflow. The roof is made of transparent corrugated plastic, with a 38o slope. There are upper and lower vents to allow fresh incoming air to replace the moisture-laden air. Two 16” diameter fans placed high and near the back of the kiln ensure air movement, as long as the sun is shining. The fans are powered by the sun, each being connected directly to a solar panel. There are no complex controls; if the sun isn’t shining, the fans don’t turn. Also, across the top of the woodpile is a horizontal sheet of plywood, painted black, to absorb heat from the sun.

Access to the kiln is simple. The roof hinges up and the low front wall hinges out and down. When the moisture content of the wood falls to 6%, we remove the wood and replace it with a new load. We try to load the kiln with species of similar drying times, as the variation between species can be a concern (i.e. oak can take several months to dry).